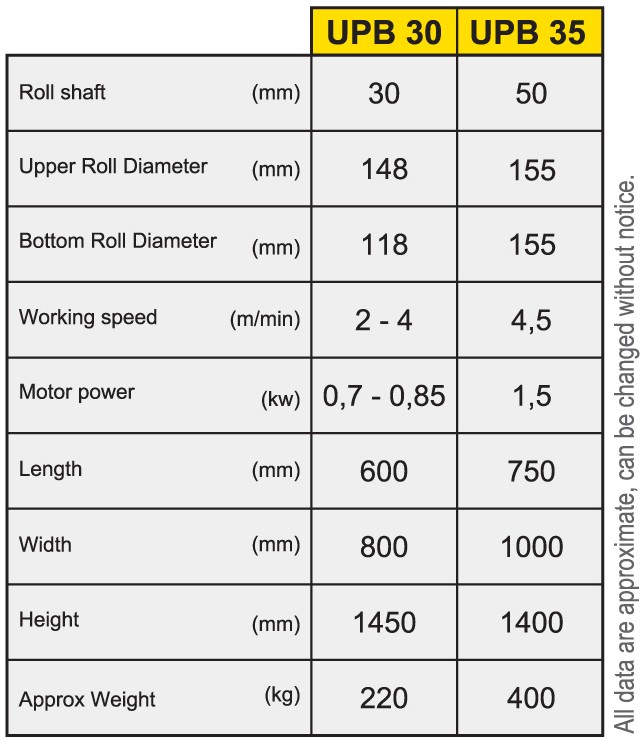

UPB 30 - UPB 35 Standards

• Steel frame

• Two rolls direct driven bya gear system

• Rolls are hardened

• Rolls shafts are special steel material hardened andground

• Roll shafts housed by bearings

• Adjustable guide rolls

• Horizontal and vertical working positions

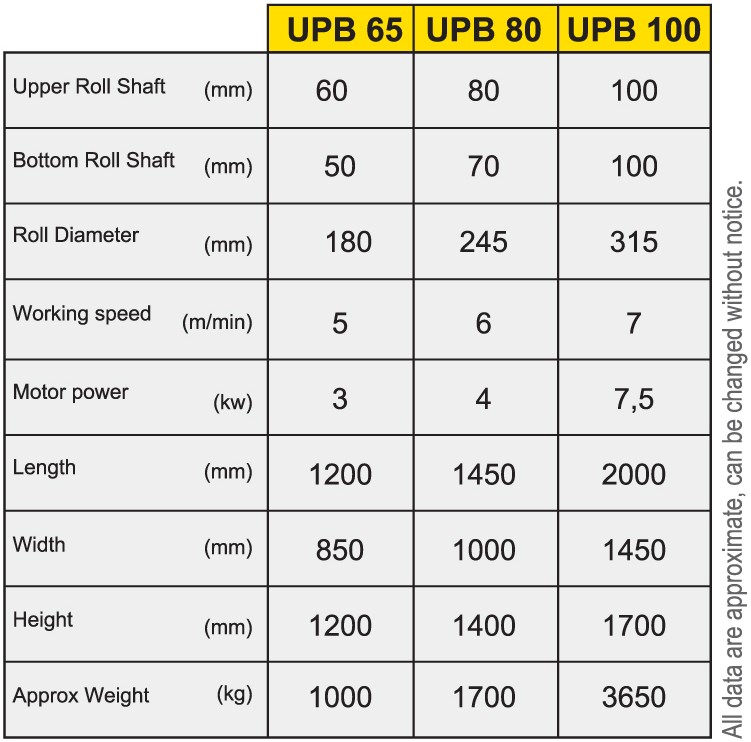

• Steel welded construction frame

• 3 Rolls are motor driven

• Hardened shafts from special steel material

• Top roll hydraulic moveable up-down

• Horizontal and vertical working position

• Standard rolls

• Guide rolls

• Brake motor equipped for the precision bending

• Mobile control panel

• Steel construction welded frame

• Hardened and ground shafts made of high tensile special steel

• Rolls are hardened and ground

• Horizontal and vertical working position

• Hardened standard rolls

• Mobile control panel

• 3 Axis mechanical lateral angle guide rolls

• Brake motor equipped for the precision bending (UPB 65-80)

• Digital read-outs (2pcs

• 3 Rolls are powered (UPB 65-80)

• 3 Rolls are hydraulic powered by planetary gearbox (UPB 100)

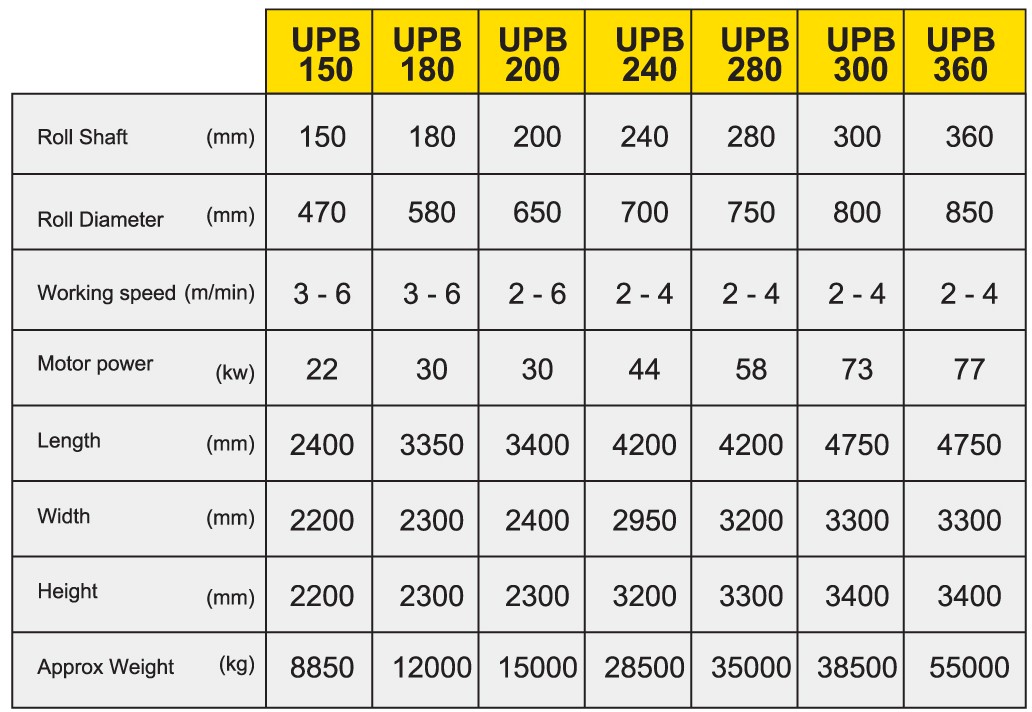

• Steel construction welded frame

• 3 Rolls are powered by hydromotor and planetary gearbox separately

• Hardened and ground shafts made of high tensile special steel

• Hardened standard rolls

• Mobile control panel

• Only horizontal working position

• Two speed working system

• Digital read-out (1 pes)

• 3 axis hydraulic lateral angle guide rolls