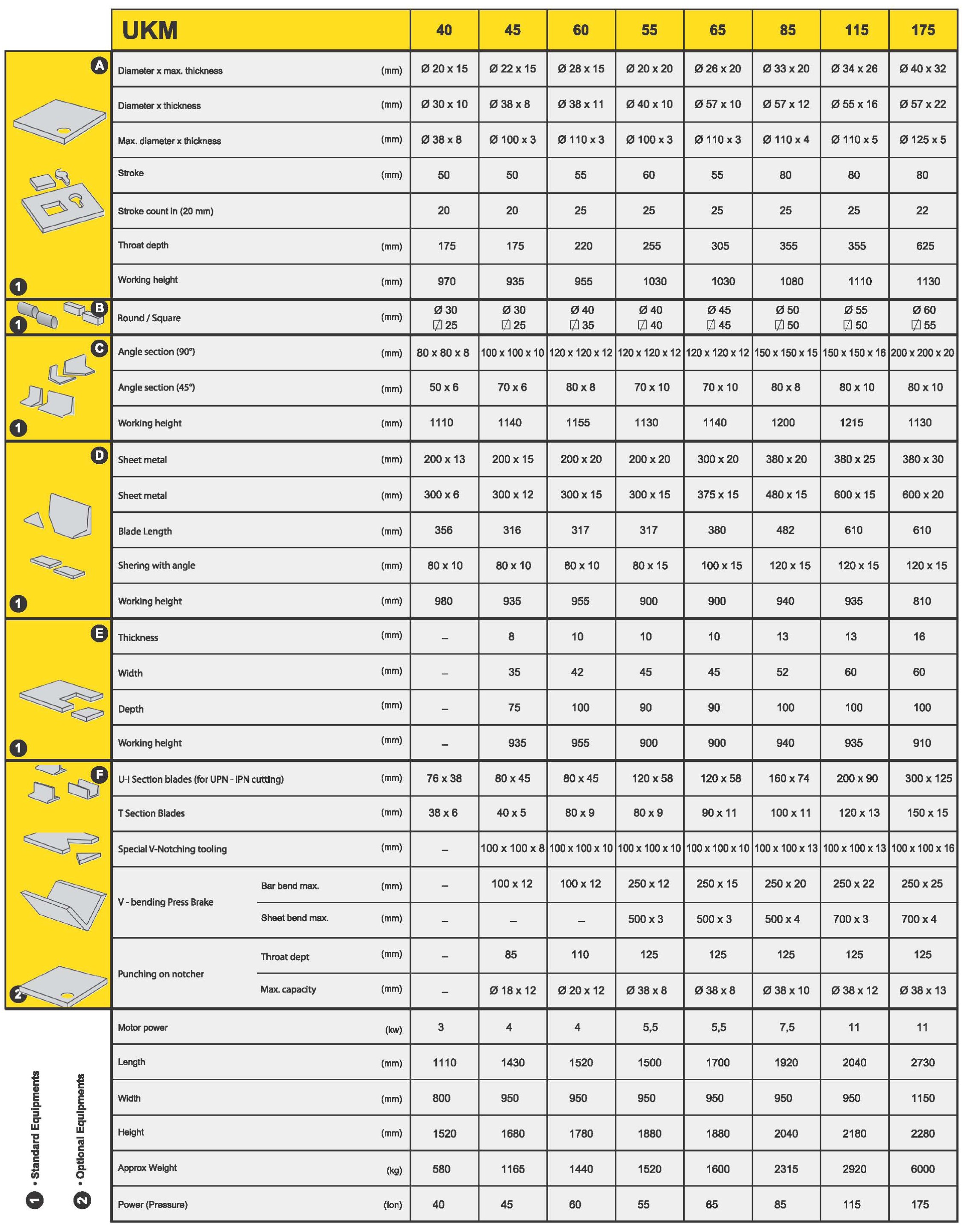

UKM series UPTEC Iron Workers are produced as single cylinder and double cylinder models. The single cylinder models has 4 standard stations and the double cylinder models has 5 standard stations, which is capable of a wide range of applications. UPTEC iron workers built for high power, quality, reliability and this very durable machines are ideal for cutting all range of angle, I beam and U-section, straight or 45°. Multi station work enables punching, cutting, notching on the same machine.

WORK STATIONS

1-Punching:

With the punching tool, different diameter holes at different thicknesses can be made easily and efficiently. The punches and dies are interchangable and easy to change. Special tools and punches are avaliable upon request.

2-Steel Bar Shearing:

With this part of the machine square and round bars can be cut quickly. By changing the tools you can also cut U-I or T sections. Special blades are available upon request.

3-Angle Shear:

Here with the help of special blades you can cut several types of any angle at 90° or 45°angle sections efficiently.

| Capacity Table & Technical Datas 4-Sheet Metal Shear:

You can do daily sheet metal cutting jobs very easily with shear station.

5-Notching:

The machine comes with a rectengular notching tool which you can use for general purpose. Special V- notching tools are also avaliable upon request.